Sustainability

Setting a new standard

Sustainability is part of Hyfer Objects' DNA. Hyfer Objects was founded on the idea that design objects do not have to equal an abundance of finite natural resources and that waste materials can be converted into higher value.

SOURCING MATERIALS

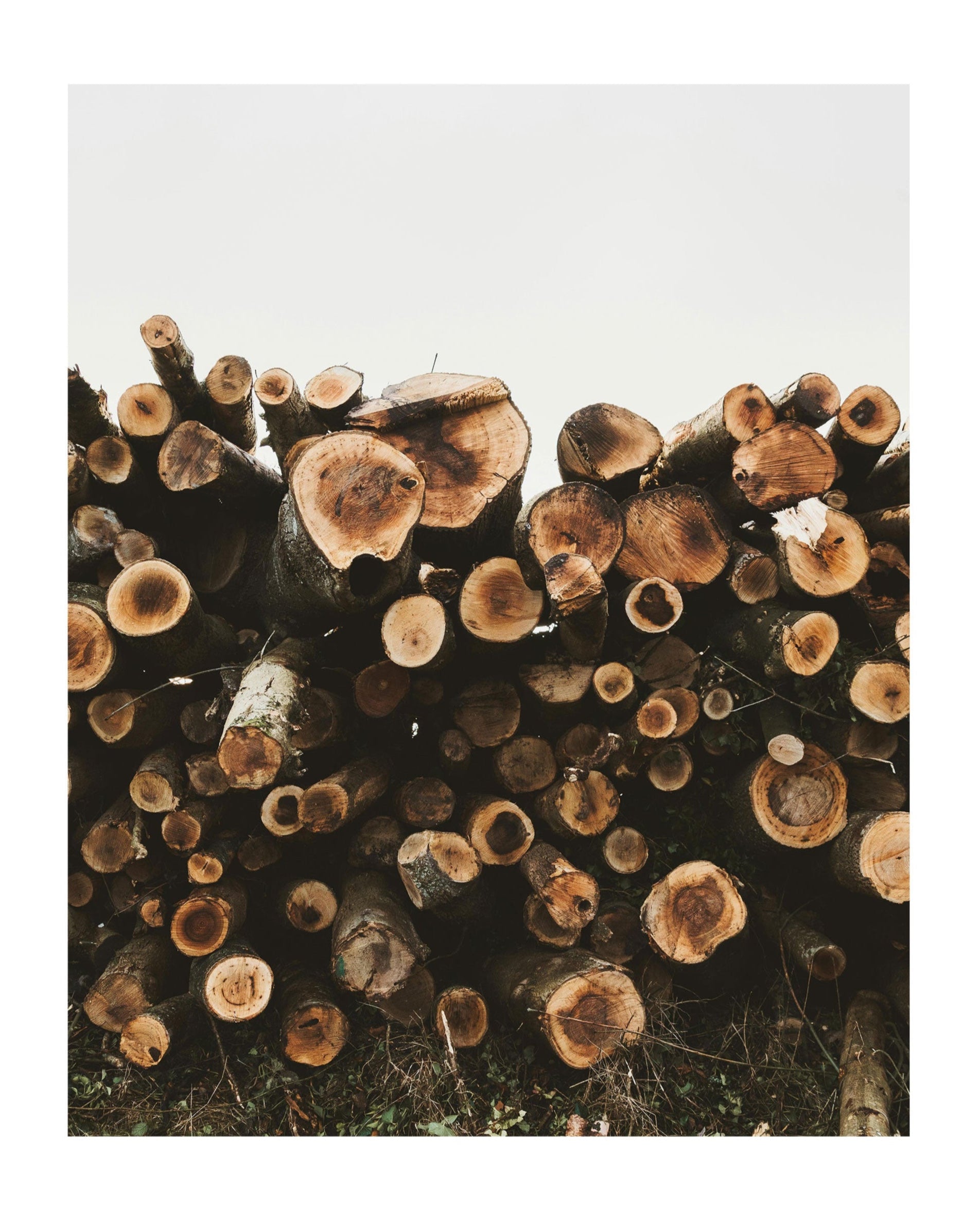

There is an abundance of materials available ranging from new raw materials to industrial waste materials. Hyfer Objects aim to, wherever possible, choose waste materials, which include industrial by-products, post production scraps, post consumer waste and more. When new materials are necessary, we select them carefully based on their quality and durability to ensure long product life.

Our goal is to keep materials in a circular loop for as long as possible. The majority of the materials we use are recyclable, and many can be ground down and reused in new products, minimizing waste and extending the lifecycle of the resources.

One key example is the main material in our furniture, which consists of approximately 70% wood scraps from the Scandinavian and Baltic forest industries combined with a recycled wax polymer. This material stores CO2 throughout its lifespan, as long as it is not burned. Even when a product reaches the end of its life due to damage or wear, the material can be reground and reused, helping to keep the carbon stored and the material in a circular loop.

every detail considered

Sustainability is at the core of everything we do, from reducing packaging to prioritizing recycled and waste-based materials throughout our operations. We continuously work to minimize our environmental footprint by streamlining our packaging to use as little material as possible, and whenever possible, we choose recycled alternatives.

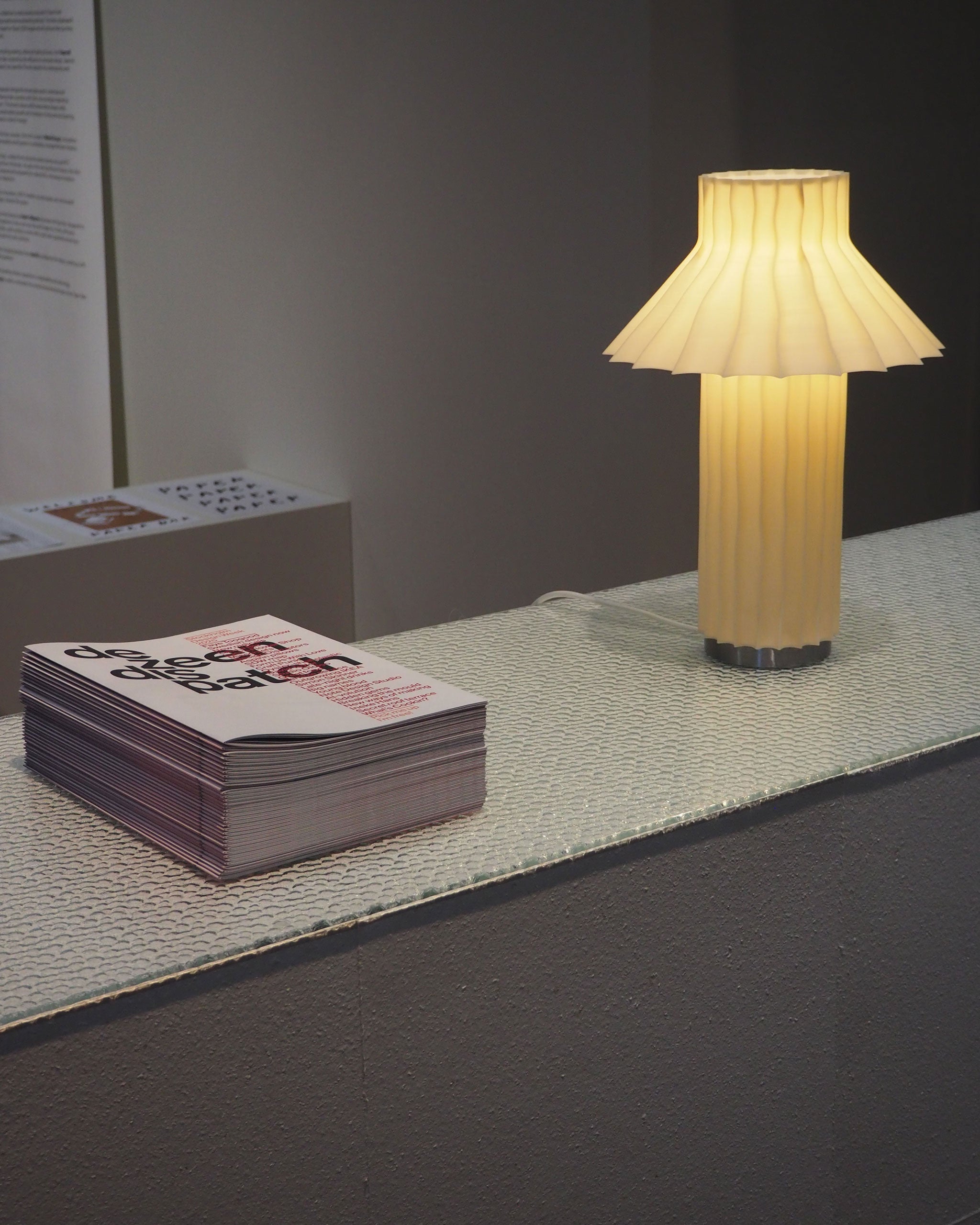

At the Stockholm Furniture Fair in February 2025, we showcased this commitment by building our exhibition stands entirely from materials made using packaging waste.

We proudly collaborate with like-minded brands that share our vision of reducing waste. These partnerships allow us to use innovative materials where different forms of waste are repurposed into high-quality products, further supporting a circular and more responsible approach to design.

Designing for the future

The majority of our products are currently manufactured using digital manufacturing methods such as 3D printing. This production method allows us to use a wide range of materials, especially waste materials, and helps minimize the creation of new waste during production. It also allows for greater flexibility and opens up new possibilities for creativity in design.

While a digitized production process may be perceived as purely technical and impersonal, the design process behind each product is deeply hands-on and thoughtful. We invest a great deal of time and care in the development of each piece, from hand-drawn and digital sketches to physical prototypes made of paper and clay. Craftsmanship remains at the heart of everything we do.

One of the great benefits of digital production is the potential for local manufacturing. By producing closer to where our customers are, we can reduce the need for global shipping and its associated environmental impact. Today we manufacture our products locally in Sweden, but as we grow we plan to manufacture locally on a global scale.

At Hyfer Objects we set high standards for our partners and suppliers. We require transparency throughout the value chain, demand energy efficient production practices and request climate data, all to ensure that we can provide honest, traceable information to the end user.